Injection Molding - Best Way to Handle Plastic

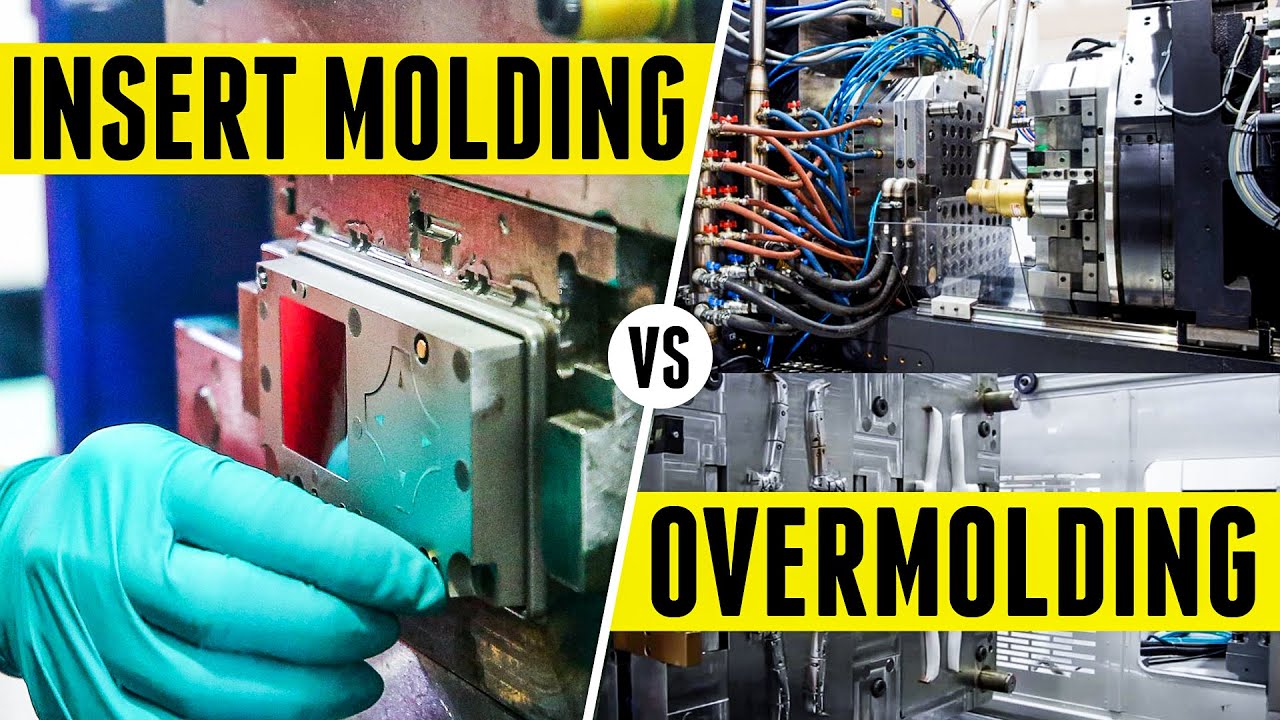

Injection molding is widely utilized: The most widely used technique for producing plastic parts worldwide is injection molding. The aerospace, medical equipment, and automotive industries all employ this technology extensively. Even the most complex parts can be produced with exacting precision in these industries thanks to the employment of cutting-edge technologies like over molding and insert molding. You'll see why millions of businesses in some of the most demanding sectors of the global economy use injection molding once you take it into consideration. 2. The ideal method for processing plastics is injection molding: Making different parts and things out of plastic through the method of injection molding. The same copy can be produced using an injection molding machine and filled precisely to specifications using a custom plastic injection molding die. More importantly, injection molding is a flexible technique that can work with a variety of materials and finish