What Are the Advantages of Using Plastic Injection Molding?

If you are considering injection molding for the production of plastic parts of any kind, you have made the right decision due to the numerous advantages. Affordability, durability, consistency, efficiency, and, most importantly, low-cost production scalability are some of the advantages. Let's discuss the advantages:

1. Effectiveness

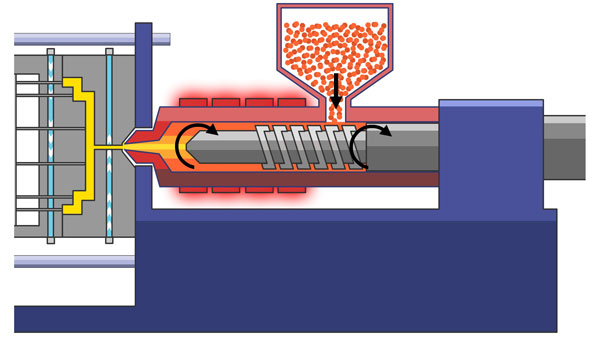

Efficiency is one of the few factors to consider when manufacturing plastic parts. As a result, careful selection and collaboration with a professional injection molder are critical to the program's success. They should be intimately familiar with manufacturing, part design optimization, and the most efficient way to mold the parts. In addition, experience is required to anticipate and prevent any production bottlenecks or problems that may arise down the road. Depending on the type of parts and plastic materials used, there are numerous processes available for optimizing the injection molding process's efficiency.

2. Stability and Durability

In the market, there is a wide variety of polymers for a wide range of applications. Strength and durability are two of the most popular plastic material selection criteria. The ability to withstand impact is measured as strength, and the ability to withstand wear and tear as well as weather resistance is measured as durability. As plastic material research advances, new additives and manufacturing processes result in plastic materials that are not only stronger and more durable, but also lighter. Furthermore, because plastics are widely used outdoors, and newly improved plastic materials can withstand harsh environments. Injection molding gives your plastic parts the strength and durability they need to withstand most challenges.

3. Precise And Complex Geometry

With advancements in plastic material research, precision machining, and plastic injection mold development, it is now possible to injection mold very complex part geometry with tight tolerances. If the part geometry is properly developed and the injection molding tooling and process are thoroughly thought out. It would be possible to produce extremely complex and highly precise molded parts much more economically and easily than other forms of mass production.

CONCLUSION

Plastic injection molding offers superior unit economics, scalability, versatility, and consistency in the production of plastic parts while leaving a small environmental footprint because the majority of scrap from the manufacturing process is recycled. So, by using a plastic injection mold to produce our plastic parts, we not only increase our bottom line but also protect the environment. If you are searching for the top plastic injection manufacturers to meet all of your needs, contact Advantage Plastics right away.

Comments

Post a Comment